Terra Silicon™

High-performance silicon anodes designed for

scalability, compatibility, and real-world impact.

The global demand for lithium-ion batteries is accelerating, fueled by electric vehicles, consumer electronics, power tools, and aviation. As these industries push the limits of performance, silicon has emerged as one of the most promising anode materials for next-generation batteries. With a theoretical capacity of ~3,600 mAh/g—more than ten times that of conventional graphite anodes — silicon has the potential to significantly increase energy density, enable faster charging, and unlock new possibilities for high-performance applications.

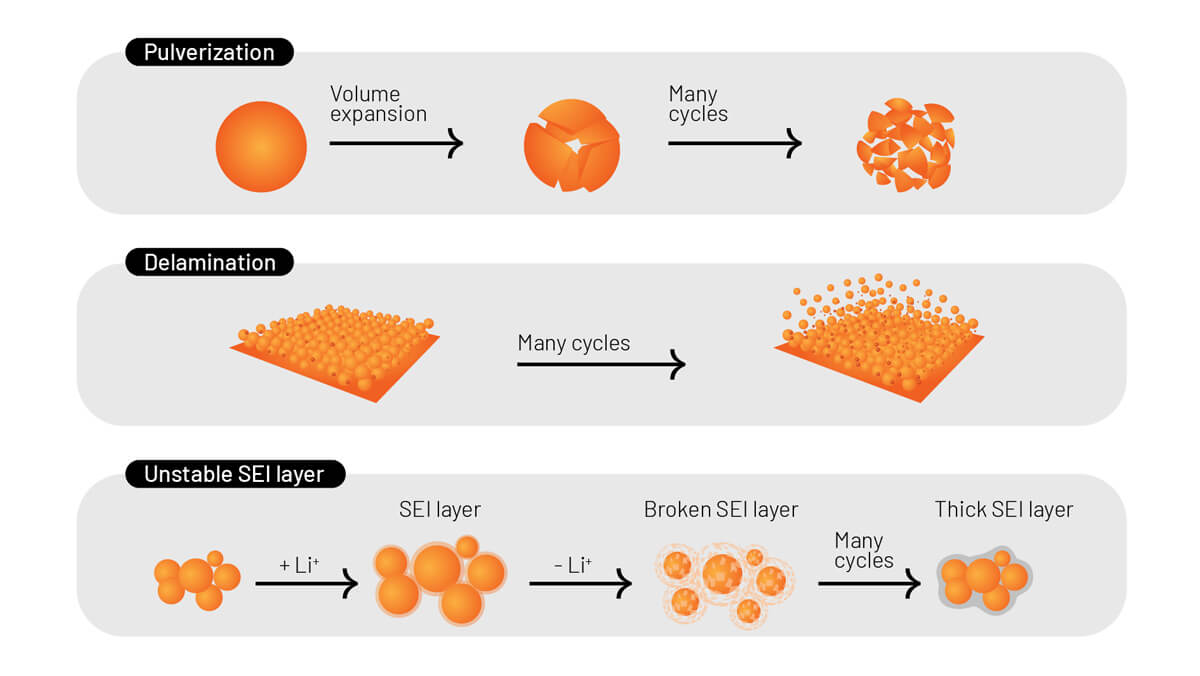

However, silicon's potential has long been held back by technical hurdles. During charging, it expands nearly 300%, leading to particle breakage, unstable interfaces, and rapid performance loss. Its poor conductivity further restricts power and charging speed. Academic fixes like composites and porous structures exist but are hard to scale. Commercial options—Si-graphite blends or SiOx—sacrifice efficiency and underuse silicon's promise. Overcoming these barriers is crucial to bringing high-silicon anodes into mainstream batteries.

Patent pending for Wrinkled

Porous Terra Silicon™

Production scale-up in progress

Customer sample requests open

Terra Silicon™ is HKG Energy’s first-of-its-kind wrinkled porous nanostructure silicon anode material, designed to replace graphite in lithium-ion batteries. Its unique architecture accommodates silicon’s natural expansion, enabling ultra-high loading (>70%) and delivering a step-change in performance—up to 450 Wh/kg energy density, fast charging in under 15 minutes, and approximately 40% cost reduction at the cell level.

Terra Silicon™ employs a wrinkled, porous nanostructure that provides internal free volume to accommodate silicon’s >300% volumetric expansion during lithiation. The wrinkled morphology dissipates mechanical stress, while interconnected pores buffer structural changes and maintain electronic and ionic pathways. This architecture prevents particle pulverization and electrode delamination, thereby enabling high silicon loading (>70%) with stable cycle life and sustained performance.

Compared to conventional graphite anode batteries, Terra Silicon™ batteries deliver 2× higher energy density, 4× faster charging, 40% lower cost/kWh, and>1,000 charging cycles.

Yes. Terra Silicon™ is designed for drop-in integration into existing gigafactory processes and is compatible with pouch, cylindrical, and prismatic cell formats.

Unlike competitors that typically use low silicon blends (5%) to avoid issues of volume expansion and instability, Terra Silicon™ enables high silicon loading (70%), unlocking a step-change in battery performance of up to 80% improvement over today’s best solutions. This breakthrough is achieved through our proprietary wrinkled porous structure, advanced conductive coatings, and a manufacturing process designed for scalability and cost efficiency. In contrast to incremental approaches, Terra Silicon™ offers a fundamentally different path—delivering higher energy density, faster charging, and lower costs at commercial scale.

Yes. Terra Silicon™’s wrinkled porous nanostructure is inherently compatible with both liquid and solid-state electrolytes. The internal pore network facilitates uniform lithium-ion transport and accommodates interfacial stresses, mitigating dendrite formation and mechanical failure that typically limit solid-state integration. This adaptability positions Terra Silicon™ as a future-ready anode material, enabling next-generation solid-state batteries with energy densities exceeding 600 Wh/kg.

We welcome collaborations for pilot testing, joint development, and scale-up manufacturing. Interested partners can reach out via our website or contact our team directly at contact@hkgenergy.com.